There has been much excitement around the potential of green hydrogen to augment and even solve our energy needs. Leaving aside production, the biggest sticking points for the development of the hydrogen economy have been the subsequent storage, handling and shipping of hydrogen. EPRO Advance Technology’s (EAT) Si+ powder product could revolutionise the burgeoning hydrogen industry, offering a safe means of producing, storing and shipping hydrogen, akin to transporting sand, making use of existing transportation infrastructure.

Just don’t EAT it!

– Futureworld

The NewAtlas article by Loz Blain details the technology…

Stir this silicon-based powder into water, and hydrogen will bubble out, ready for immediate use. Hong Kong company EPRO Advance Technology (EAT) says its Si+ powder offers an instant end to the difficulties of shipping and storing green energy.

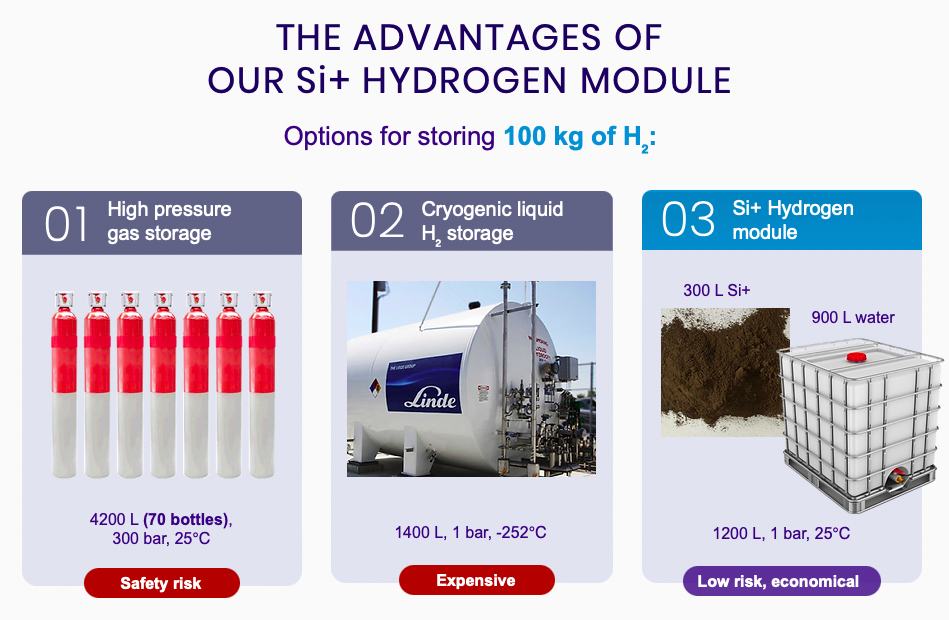

This is the second powdered hydrogen advance we’ve learned about this week, designed to solve the same problems: transporting hydrogen is difficult, dangerous and expensive, whether the costs are for cryogenic cooling in a liquid hydrogen system, or for compression to around 700 times the normal sea-level air pressure.

But where Deakin University’s mechanochemical storage process takes hydrogen gas and traps it in a powder for easy, stable transport, releasing it only once the recyclable powder is heated, EAT’s silicon-based powder doesn’t require you to start off with any hydrogen at all – and getting the hydrogen back out is even easier.

The Si+ powder can be made using a (preferably renewable) energy source, as well as metallurgical-grade silicon – which itself can be made from sand, or from crushed-up recycled solar panels and electronics. EAT’s process results in a porous silicon powder that’s completely safe and easy to transport.

When you need the hydrogen, you dump the Si+ powder into water, mix it around a bit, and … that’s pretty much it. At a wide range of ambient temperatures between 0-80 °C (32-176 °F), hydrogen gas will start bubbling out. The chemical equation, says EAT, looks like this: Si + 2H2O -> SiO2 + 2H2. Thus, apart from the hydrogen gas, all that’s left over is silicon dioxide, also known as silica, or the major constituent of sand. EAT says this can be shipped off to make concrete, or zeolites.

This will be much, much easier to transport than pure hydrogen. EAT gives the example of the world’s first hydrogen-shipping ship, the Suiso Frontier, a 116-meter (381-ft) cargo ship that can carry 88.5 tonnes of hydrogen, cryogenically cooled into a liquid state at great expense. The Si+ powder will weigh more, but it’ll also take up a whole lot less space. The same amount of hydrogen can effectively be carried in about 33 shipping containers full of Si+ powder, so a standard cargo ship’s ~10,000 container capacity represents the ability to carry ~30,000 tonnes of hydrogen – or 339 times more than the Suiso Frontier.

Weight is definitely a factor – the Si+ powder weighs about 7.4 times as much as the hydrogen it can generate. But this represents a mass fraction around 13.5%, which is nearly double what the Deakin powder promises, and it could actually end up being weight-competitive with a compressed gas system given how heavy those tanks tend to be. (however, there are promising hydrogen storage technologies being developed offering a mass fraction of 10-11%; Ultra- light storage tanks promise to make jet fuel obsolete – Futureworld)

The biggest missing numbers here to us are cost and energy input – will Si+ powder compete with pure hydrogen or powdered hydrogen on cost, and how much more renewable energy will it cost to produce this stuff than an equivalent energy value run through an electrolyzer and a ball milling process? Such details are still to be released by EAT.

Meanwhile, EAT says it’s already got its system in front of the Hong Kong Airport Authority, which is evaluating it as a way to fuel a clean replacement to its backup gensets. The company says it’s got a pilot production line online, and it’s ready to scale up and fully commercialize the innovation once the right partnerships are in place.

If Si+ really does what it says on the tin, and it’s not too expensive or energy-inefficient, this could certainly represent a significant step forward, particularly for green energy exporters and distributors. It appears to be an even higher-density carrier of “potential” hydrogen, with a simpler release process, than the Deakin powder, and it’s every bit as safe and easy to transport or store.

Via NewAtlas, written by Loz Blain 21 July 2022

- Articles