Cement is the most widely used material on the planet, originally derived from the liberation of carbon from limestone through intensive heating, releasing significant carbon dioxide volumes in the process. Biomason uses natural microorganisms to produce an improved cement substitute, providing a signal of just how different the future could be. Producing biocement in ambient conditions without emitting carbon dioxide has the potential to have far reaching ripple effects across multiple industries.

– Futureworld

The Fast Company article by Adele Peters elaborates…

Inspired by Biomimicry, and more specifically, biomineralization, the process that forms coral reefs and shells, architect Ginger Krieg Dosier considered the fundamental sustainability challenges of the materials in her industry; ultimately becoming inspired to start a company called Biomason, which just raised $65 million to scale up its technology. The company’s process uses natural microorganisms to produce cement—one of the world’s most polluting products—more sustainably.

Cement, the glue that holds together concrete, has a massive carbon footprint that makes up around 8% of global emissions, four times more than the airline industry. In fact, the world now produces more than 4 billion tons of cement each year, and making it takes a lot of energy: The key step involves using fossil fuels to heat up limestone to 2,732 degrees. Burning limestone also releases CO2 directly.

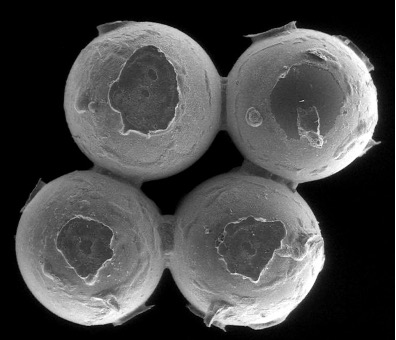

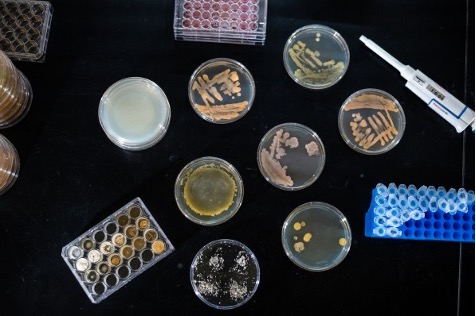

To make its first product, a tile that it calls Biolith, the company starts with recycled aggregate, the tiny bits of material that cement holds together in concrete. Then it adds its (safe) strain of bacteria, along with calcium, carbon, and nutrients. The combination jump-starts the creation of calcium carbonate, the “biocement” that acts like glue. Unlike traditional cement manufacturing, it works in ambient temperatures, without the need for high heat. It also cures in days, while traditional Portland cement takes weeks. The resulting product is also stronger than a traditional concrete block because of the way the material forms naturally.

Other start-ups are tackling cement emissions in a variety of ways, including injecting captured CO2 into the product or replacing standard limestone with another type of rock that doesn’t emit CO2. It’s possible that multiple new approaches will begin to replace traditional cement manufacturing. But Biomason is unique in its use of biology, and the biological approach means that its products can work differently in different settings.

With funding from the U.S. Department of Defence, the company has also designed “living marine cement” for use in seawalls or other underwater applications. If the concrete develops a crack, it can pull calcium and carbon from the water to heal itself.

Currently, Biomason makes small quantities of up to 20,000 square feet of the tile for commercial clients at its facility in North Carolina. But it’s also scaling up larger production with IBF, the largest concrete producer in Denmark, which will increase its capacity by 2023. Other concrete producers will also license the technology. The process is designed to fit in seamlessly at concrete plants.

“It didn’t make sense to disrupt everything in the entire concrete value chain,” Krieg Dosier says. “From day one, even before Biomason was named, it was very important for us to develop a technology that was easy to use, especially with existing concrete producers.”

Biolith tiles have been installed in several buildings, including H&M’s headquarters, where the retailer is exploring the use of the tiles in new brick-and-mortar stores. But current sales are still an infinitesimally tiny part of the overall market for concrete. With the new funding, Krieg Dosier plans to take the next steps to grow Biomason, including developing a process that can be used in ready-mix concrete, not just premade tiles. Ready-mix concrete makes up about 85% of the market.

The demand keeps growing as architects, cities, and companies look for ways to shrink emissions. “Cement has come under scrutiny and investigation, trying to figure out what we can do,” Krieg Dosier says. “I actually think that there’s a big shift right now. There’s a scramble to figure out, How are we going to solve this problem?”

Via Fast Company, written by Adele Peters, 25 February 2022

- Articles