Realising the extent of the environmental harm resulting from the use of plastics in our society, there has been much focus on addressing the sheer volume of plastic waste in the environment. While there are multiple novel ideas under differing levels of development to address this problem, the past decade has seen scientists investigating the potential of enzymes in aiding the recycling of plastics, with considerable advances in recent years, as outlined in the New Atlas article “Fast-acting enzyme breaks down plastics in as little as 24 hours” by Nick Lavars 27 Apr 2022.

However, such solutions only address the disposal and end of life treatment within the plastic value chain, while innovative ideas often involve a rethink of the production, manufacture and / or use. Researchers at Rutgers School of Public Health appear to be making progress in this area, having developed a coating that has the potential to replace plastic food packaging, with the potential to significantly disrupt the industry offering truly sustainable packaging.

– Futureworld

Researchers from Rutgers School of Public Health have developed a coating that can be sprayed on food – and say it keeps products fresh for 50 per cent longer. The team hopes their plant-based coating could soon replace plastic packaging in supermarkets.

‘We knew we needed to get rid of the petroleum-based food packaging that is out there and replace it with something more sustainable, biodegradable and nontoxic,’ said Philip Demokritou, an author of the study. And we asked ourselves at the same time, “Can we design food packaging with a functionality to extend shelf life and reduce food waste while enhancing food safety?”

‘What we have come up with is a scalable technology, which enables us to turn biopolymers, which can be derived as part of a circular economy from food waste, into smart fibres that can wrap food directly. ‘This is part of new generation, “smart” and “green” food packaging.’

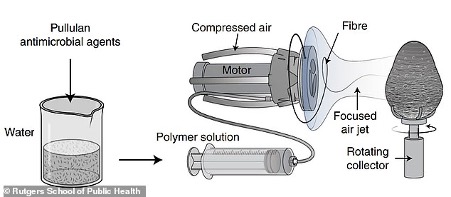

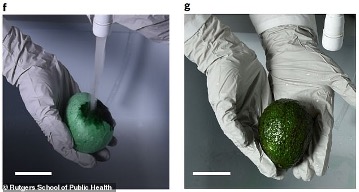

The packaging uses fibres made from polysaccharides – the most abundant carbohydrates found in food. These fibres are spun from a heating device that resembles a hair dryer, before being ‘shrink-wrapped’ over foods including avocados or steaks. The fibres are laced with thyme oil, citric acid and nisin – naturally occurring antimicrobial ingredients that fight spoilage and pathogenic microorganisms such as E. coli and listeria.

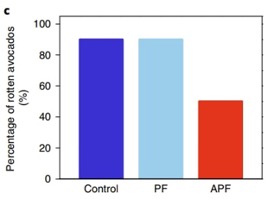

The coating can not only help to prevent spoilage, but is also sturdy enough to prevent bruising, according to the team. Once you’re ready to eat the food, the coating can simply be rinsed off with water, and degrades in soil within three days. During testing on avocados, the researchers found that the coating helped to extend the fruit’s shelf-life 50 per cent.

Best of all, the researchers have shown the scalability of their approach. While popular fibre-production techniques currently spin fibres at a rate of 0.01 grams/minute, the researchers’ new technique can produce fibres at a much higher production rate of 0.2 grams/minute.

The team hopes the new packaging could help with efforts to curb the use of plastics in supermarkets. ‘Over the past 50 to 60 years, during the Age of Plastic, we’ve placed 6 billion metric tons of plastic waste into our environment,’ Dr Demokritou said. ‘They are out there degrading slowly. ‘And these tiny fragments are making it into the water we drink, the food we eat and the air we breathe.’

Source: Mail Online

Via Mail Online, written by Shivali Best 20 June 2022

- Articles